Heavy Metal Treatment

Our heavy metal treatment technologies are based on the experiences on non-metal refining industry.

We can provide the best solutions for the individual process in the light of the specifications such as coexisting materials, required water quality and so on.

- Object substances

-

- Heavy metals

- Light metals (Aluminum etc.)

- Precious metals

- Half metals and Semiconductors (Silicon etc.)

- Alkaline earths (Calcium, Magnesium etc.)

- Rare earths

- Cyanide

- Organic compounds (COD)

- Oxidizing and/or Reducing agent (Hydrogen peroxide, Residual Chlorine etc.)

など

Achievements

Waste water treatment for Pickling process

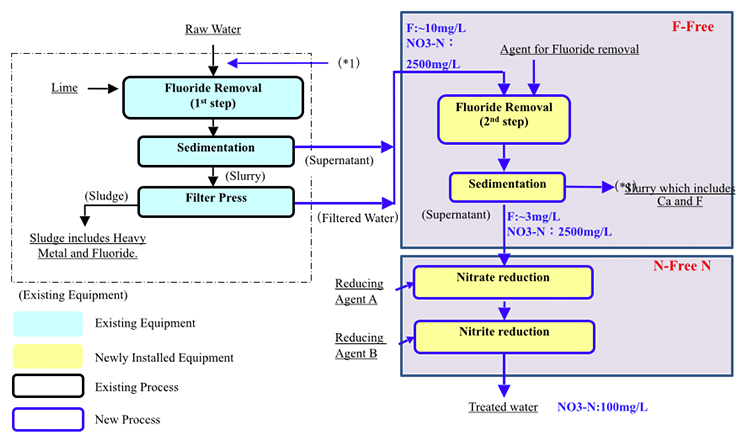

This is the achievement which is applied to the waste water treatment of pickling.

The waste water includes Nitric acid, Hydrofluoric acid and heavy metals.

We applied F-Free for removing Fluoride and Calcium, and N-Free N for removing Nitrate-nitrogen after removing heavy metals and Fluoride by customer’s equipment.

Waste water treatment for Semiconductor material washing process

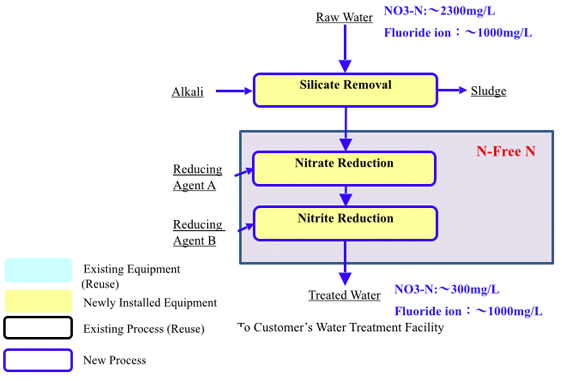

This is the achievement which is applied to the semiconductor material washing process.

We applied N-Free N for reducing Nitrate and Nitrite after removing Silicate.

Customer will treat Fluoride with the existing treatment facility.

Combination with Water recovery

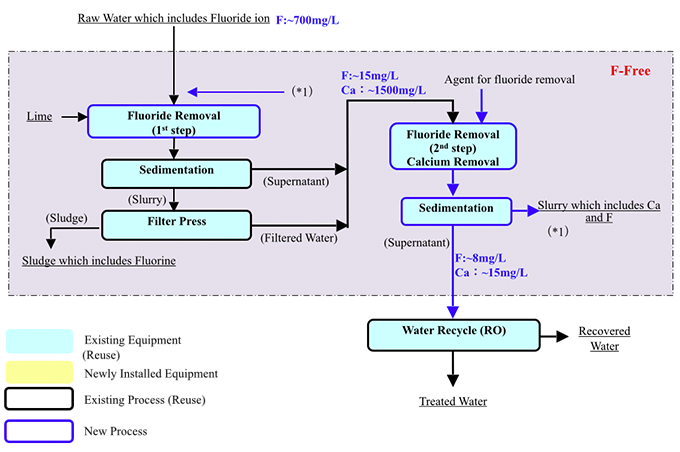

This is the achievement which is applied to the water treatment combined with the water recycle.

We applied F-Free for remove Fluoride and Calcium.

And then customer will recover the water by using RO equipment.

Combination with Acid recovery

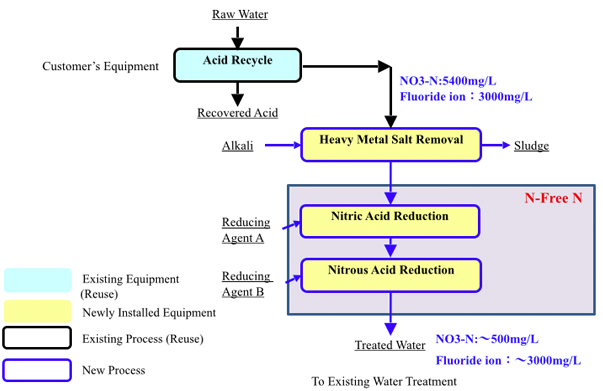

This is the achievement which is combined with the acid recycle system.

After recovering acid by the existing equipment, we applied heavy metal removal equipment as pretreatment, and then applied N-Free N for reducing Nitrate.

Customer will treat Fluoride by using the existing water treatment system.

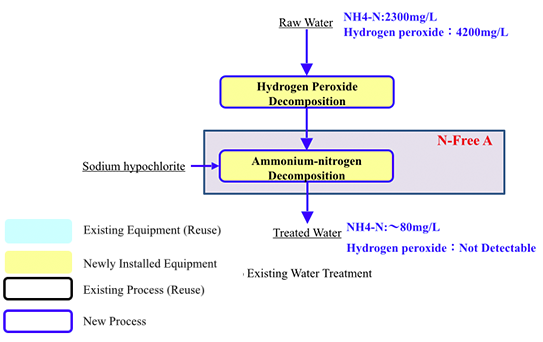

Waste water treatment for Electronic device etching

This is the achievement which is applied to the electronic device etching process.

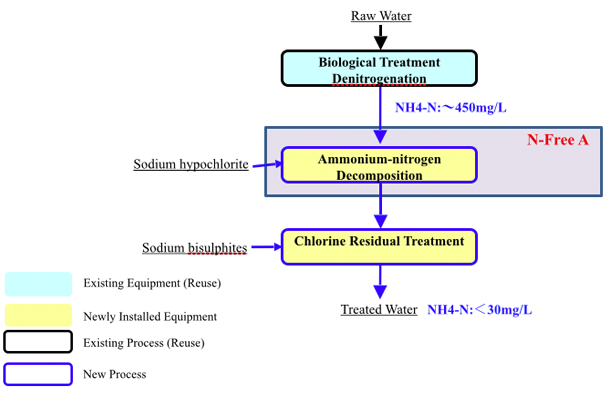

Because the amount of Ammonium-nitrogen is relatively small, we applied N-Free A as Sodium hypochlorite dosing system for decomposing Ammonium-nitrogen instead of the electrolytic technology.

Hydrogen peroxide decomposing system is installed before Ammonium-nitrogen treatment because the raw water includes Hydrogen peroxide.

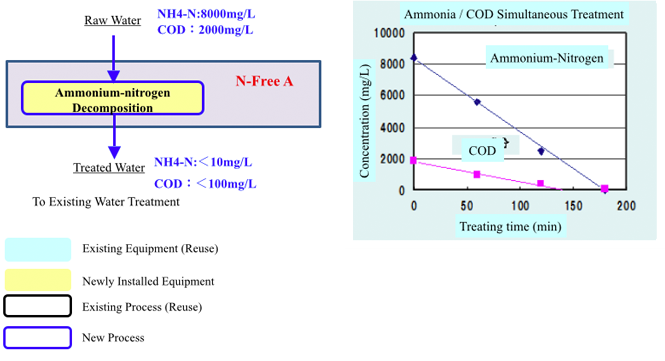

Waste water treatment for Chemicals production

This is the achievement which is applied to the waste water treatment for the Chemicals production.

We applied N-Free A for decomposing Ammonium-nitrogen and COD components (organic compounds) simultaneously using the electrolytic technology.

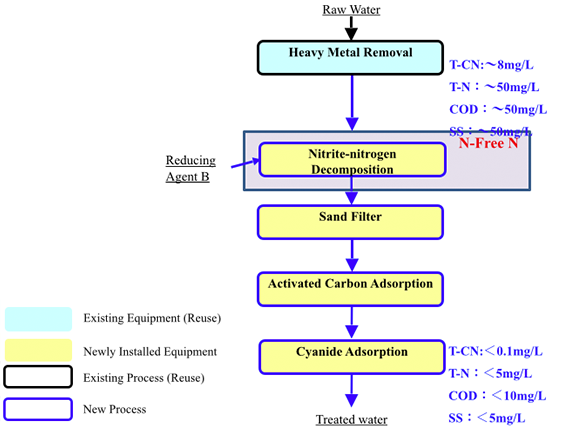

Waste water treatment for Exhaust gas treatment equipment

This is the achievement which is applied to the waste water treatment which is generated from the exhaust gas treatment equipment.

After removing heavy metals by the existing equipment, We applied N-Free N for decomposing Nitrite-nitrogen, and treatment system for removing Suspended Solid, COD and Cyanide.

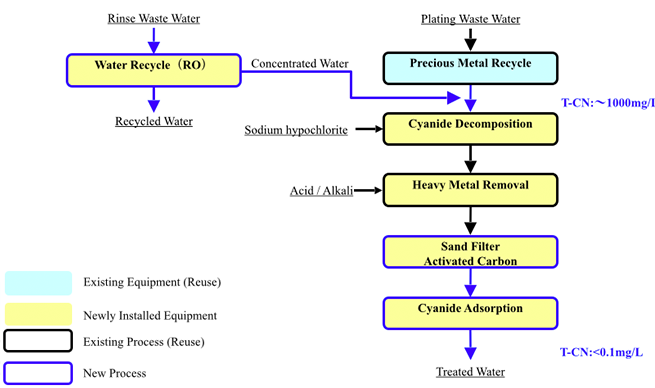

Combination of Plating process waste water treatment and Water recycle

This is the achievement which is applied to combination process of the plating waste water treatment and the water recycle system.

The system recovers the water from rinse waste water by using RO, and then treats the concentrated water and plating waste water to remove Cyanide and Heavy metals.

Seepage water treatment for Industrial waste final disposal site

This is the achievement which is applied to the Seepage water treatment for Industrial waste final disposal site.

We applied N-Free A as Sodium hypochlorite dosing system for decomposing Ammonium-nitrogen, because it is for the back-up system for the existing biological treatment when Ammonium-nitrogen load is large.

We also applied Chlorine residual treatment system after N-Free A.